Louvred Gratings

Ultra-design for challenging architectures

Louvred GEI gratings are used for façades to provide a visual screen, a brise-soleil effect or a privacy screen, as well as to form a wall that counteracts any impressions of emptiness.

Louvred GEI grating is manufactured according to a precise load table. The dimensions of the bearing bars (BB) are important because they determine the load bearing capacity of the grating.

Mesh center distance

These are decided based on standards and load capacity. For louvred grating, mesh centre distances for the BB and TB are typically in multiples of 11.11. G.E.I has a range of louvred gratings with different mesh available:

- 100 x 30 – 60 x 30 – 30 x 30.

- Other options are available on request.

Dimensions

Maximum dimensions: 2,500 x 2,000 mm.

For optimal grating quality, we advise you not to exceed a height/length ratio of 1.5 m2.

Fastening systems

Fastening systems are manufactured from galvanised steel for steel gratings and from stainless steel for stainless steel and aluminium gratings. In certain cases, gratings may be fixed to structures with welded brackets.

Fastening systems are manufactured from galvanised steel for steel gratings and from stainless steel for stainless steel and aluminium gratings. In certain cases, gratings may be fixed to structures with welded brackets.

Direction and inclination

Bearer Bar

Standard thickness: from 2 to 3 mm.

Height of BBs and TBs (in mm):

| Bearer Bar | 25 | 30 | 35 | 40 | 50 | 60 |

| Transverse bars louvred at 45° | 35 | 40 | 50 | 55 | 70 | 85 |

Material

S235JR steel as per EN 10025 standards.

304 (1.4301) or 316Ti (1.4571) stainless steel.

AlMg3 aluminium.

Finish

Finishes with banding bars

Finishes without banding bars

Manufacturing Principle

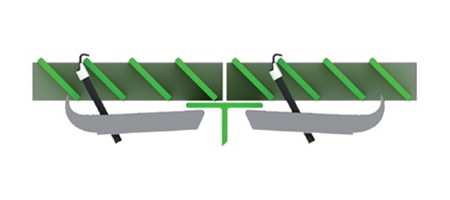

GEI louvred grating is characterized by transverse bars inserted at 45° into the bearing bars (please check with us for any other angle). It can then be produced in “flat” sections, welded at right angles to the bearing bars. The grating then optionally undergoes hot-dip galvanizing in accordance with the applicable EN ISO 1461 standards. G.E.I louvred grating is typically manufactured from EN 10025 standard S235JR steel which ensures a consistent production quality.

Custom Manufature

Custom manufacture based on the dimensions given by the customer or on plans drawn up by our research department.

Our research department is available to handle your technical requirements and your intended layouts, and can advise you on issues up to and including the realisation of your orders.

- Sun shadings

- Decoration

- Ventilation systems

- Soundproofing

- Flooring

- Roofing

Structures

Mesh

Spacing between bearing bars (BB) and transverse bars (TB). Mesh created in this way has two characteristics: mesh width and mesh centre spacing (pitch).

- Mesh width: the width of the opening that is between the BBs and TBs

- Mesh centre spacing (pitch): the distance between the centre of BBs and TBs (for example, the distance between the centre of one bearing bar and the centre of the nearest adjacent bearing bar

Mesh group | Type

Mesh is made up of two values (in mm), where the first dimension is the distance between adjacent bearing bars, and the second dimension being the distance between adjacent transverse bars (for example: 33.33 x 33.33; 33.33 x 11.11; 55.55 x 55.55; etc.).

For convenience’s sake, the term “mesh gauge” is more frequently used (for example: 30 x 30 - 30 x 10 - 50 x 50 - etc.)

Bearing bars (BB)

Straight rods bearing the weight and arranged in rows at right angles to the transverse bars and supports.

Transverse bars louvred

Inserted at 45° into the bearing bars (contact us for any other degree of inclination), the BIs are assembled to the BPs by pressing.

BB and TB gauge

This is defined by two values (in mm), where the first corresponds to their height and the second to their thickness. Gauge examples: 30 / 2; 30 / 3; 40 / 3; etc...

Range

Gap between the supports on which the ends of the bearing bars rest.

Impermeability - Security bars

Security mesh uses the following mesh gauge: 30 x 19; 19 x 30; 19 x 19; etc. It is recommended for industrial environments (14122 standard) and allows nothing exceeding a 20 mm diameter ball to pass through it.

Angle support

Bracket welded to the ends of the grating rendering it suitable for certain uses (for example: shelving, guttering).

Material

Steel

Stainless steel

Aluminium

Finish

"Flat" banding bar

Bar which forms the outer frame of the panels.

Toe plate

Straight metal welded onto the end of the grating

Raised border

Straight metal welded onto the end of the grating

Specific applied standards

ISO 14122 : Permanent means of access to machines and industrial plants

ISO 14122-2 : Working platforms and walkways

ISO 14122-3 : Stairs, ladders and handrails

RAL-GZ 638 : Manufacturing tolerances for gratings

RAL-GZ 639 : Manufacturing tolerances for safety grids

EN ISO 1461 : Galvanisation requirements

EN 10025 : Steel standard